The application of the Bio Reactor

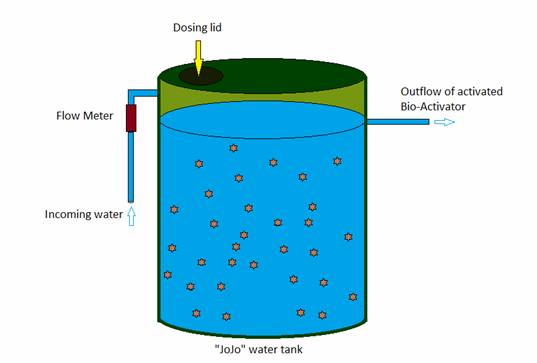

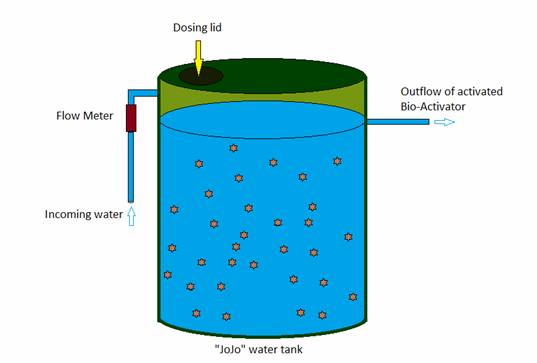

The

Bio Reactor is a "JoJo" tank, or series of tanks, which is/are installed on the

site nearest where the waste water enters the treatment plant. The

installation is non-invasive and there is no re-engineering or any form of

construction required to be undertaken by the client. Installation usually

is completed in a few hours.

The Bio Reactor requires

a 24/7 dedicated water supply in order to inoculate the waste water at the

influent point. The feeder system is both a water fed and manually fed

process. The feed material is manually fed into the tank in dehydrated form

where the water rehydrates the feed material. This feed material then feeds

the biomass within the tank.

The biomass molecules are

inoculated through a specially designed outlet valve of the tank into the

waste water pond/plant.

Once in the waste water

treatment plant, the Bio-Activator improves the bacterial metabolism of

organic material. This in turn reduces sludge levels and eliminates odours.

It operates aerobically under anaerobic conditions. It inhibits the

production of hydrogen sulphide and methane. It is very effective in

organically overloaded plants and improves the plants' ability to handle

shock loads.

The Bio-Activator

does not interfere with any of the processes anywhere in the waste water

treatment plant. In fact it enhances and improves all the organic

functions, both

anaerobic and aerobic,

throughout the system. Because this product is completely organic there is

no hazard to any fittings, pumps or any form of corrosion or any other

negative effect. It is completely safe for people, animals and crops and

it is environmentally friendly.

After the initial dosing of

the bio tank with biomass to initiate the process, the tank must be dosed

daily with a specified quantity of Bio-Activator feed material. This process

is simple and the dosing is done via the lid on the top of the tank. It does

not require any special skills or any form of protective clothing or

equipment and it can be implemented by a designated member of staff after

only a few minutes of instruction.

These photos were taken at the

waste water treatment plant of a mission hospital in Khanye in Botswana,

showing the simplicity of the system.

The pipe leading to the

concrete structure on the right is feeding the activated Bio-Activator into

the chute where the effluent from the hospital enters the waste water

treatment plant. The pipe on the left is the dedicated water supply which is

controlled by a flow meter.

This is what the "treated"

water used to look like after having been processed by the waste water

treatment plant, but before the Bio-Activator process was introduced. This

effluent is supposed to be clear at this stage where it is then subjected to

a disinfection process prior to discharge. It is evident that the waste

water treatment plant was failing dismally.

Within 12 hours after the bio

reactor being initiated the bad smells had completely disappeared. This is a sample of the final

effluent which had cleared within a week after the bio reactor was

commissioned.

The advantages of Bio-Activator:

-

Prevents the generation of

odours

-

Stops the production of hydrogen

sulphide

-

Greatly increases bacterial

metabolic rate

-

Improves the ability to handle

shock loads

-

Improves bacterial breakdown of

organic material

-

Very effective on organically

overloaded treatment plants

-

Increases treatment plant

capacity dramatically

-

Prevents ponding and solids

build-up in trickling filters

-

Increases the rate of nitrogen

cycling

Bio-Activator is suited for treating:

-

Tannery effluent

- Textile effluent

-

Distillery effluent

- Sorghum brewery effluent

- Soft drink and bottling

plant effluent

- beer brewery and

bottling plant effluent

-

Municipal Sewage and other waste

water treatment plants for hotels, resorts and

housing

complexes

- Abattoir effluent

-

It prevents

the generation of odours in landfills

Bio-Activator

positively promotes and enhances the capabilities of:

-

Anaerobic Digesters

-

Activated sludge

-

Sludge Lagoons

-

Oxidation Ponds